Global Logistics: Sea Freight – LCL vs FCL

Sea freight is the backbone of international logistics, especially for engineering goods, industrial machinery, and bulk cargo. Choosing between LCL (Less than Container Load) and FCL (Full Container Load) directly impacts shipping cost, transit time, cargo safety, and operational efficiency.

What is Sea Freight?

Sea freight refers to the transportation of goods across international waters using ocean-going vessels and standardized shipping containers. It is the most economical and scalable logistics solution for moving heavy, oversized, and high-volume cargo over long distances.

Sea freight operates through global shipping lines, ports, container terminals, and inland logistics networks, making it suitable for worldwide trade operations.

Types of Sea Freight

LCL – Less than Container Load

LCL shipping is used when cargo volume is insufficient to fill an entire container. Multiple shipments from different exporters are consolidated into a single container at a Container Freight Station (CFS).

- Shared container space

- Charged per CBM (Cubic Meter)

- Suitable for small or trial shipments

- Longer transit due to consolidation and deconsolidation

FCL – Full Container Load

FCL shipping is used when a single exporter occupies the entire container, regardless of whether the container is fully loaded or not.

- Exclusive container usage

- Flat freight rate per container

- Faster transit time

- Higher cargo security and lower damage risk

Why Choose Sea Freight for International Trade?

- Lowest transportation cost for heavy and bulky engineering goods

- Ideal for long-distance international trade routes

- Ability to transport oversized, overweight, and project cargo

- Availability of multiple container types (Dry, Flat Rack, Open Top, High Cube)

- Lower carbon footprint compared to air freight

- Stable freight pricing for bulk shipments

Where is Sea Freight Commonly Used?

Major Sea Freight Trade Routes

- Asia–Europe trade lane (Engineering goods, automotive parts)

- India–USA exports (Machinery, tools, components)

- India–Middle East (Industrial equipment)

- China–Africa & ASEAN markets

Industries Using Sea Freight

- Engineering & manufacturing

- Heavy machinery & project cargo

- Construction equipment

- Power & energy sector

- Automotive & spare parts

- Steel and metal products

LCL vs FCL – Comparative Table

| Parameter | LCL | FCL |

|---|---|---|

| Cargo Volume | Small shipments | Large shipments |

| Cost Structure | Per CBM | Per container |

| Transit Time | Longer | Faster |

| Cargo Safety | Moderate | High |

| Handling | Multiple handling points | Minimal handling |

| Ideal For | SMEs, trial shipments | Bulk exporters, heavy machinery |

Conclusion

Choosing between LCL and FCL sea freight is a strategic logistics decision that affects cost efficiency, delivery timelines, and cargo safety. For engineering goods exporters, understanding shipment size, urgency, and risk factors ensures optimized ocean freight planning and smooth international trade execution.

Sea Freight Decision Flowchart

Sea Freight – FAQs

Q1. What is Sea Freight in international logistics? ▶

Sea freight is the transportation of goods via ocean vessels using standardized shipping containers. It is the most cost-effective logistics solution for moving heavy, bulky, and high-volume cargo across international borders. Sea freight is widely used for engineering goods, industrial machinery, metal products, and bulk shipments due to its high load capacity and global reach.

Q2. What is the difference between LCL and FCL in sea freight? ▶

The main difference lies in container usage and cost structure. LCL (Less than Container Load) allows multiple shippers to share one container and is charged per CBM (Cubic Meter). FCL (Full Container Load) gives one shipper exclusive use of the entire container and is charged at a flat container rate. LCL is ideal for small shipments, while FCL is suitable for bulk and heavy engineering cargo.

Q3. When should an exporter choose LCL shipping? ▶

LCL shipping is recommended when the cargo volume is below 12–15 CBM, the shipment is non-urgent, or when exporters want to reduce upfront freight cost. It is commonly used by SMEs, first-time exporters, and exporters sending trial shipments.

Q4. When is FCL shipping the better option? ▶

FCL shipping is the better option when cargo volume is 15 CBM or more, or when shipping heavy machinery, high-value engineering goods, or sensitive equipment. FCL offers better cargo safety, faster transit time, and lower freight cost per unit, making it ideal for bulk and repeat shipments.

Q5. Which is more cost-effective: LCL or FCL? ▶

LCL has a lower initial cost but a higher cost per CBM, while FCL has a higher upfront cost but becomes more economical for larger shipment volumes. For exporters shipping regularly or in bulk, FCL is more cost-effective in the long run.

Q6. Is cargo safety better in LCL or FCL? ▶

Cargo safety is generally higher in FCL shipments because the container is handled only once and sealed by a single exporter. LCL shipments involve multiple handling points during consolidation and deconsolidation, increasing the risk of damage or delay.

Q7. What types of goods are suitable for sea freight? ▶

Sea freight is suitable for engineering goods, industrial machinery, construction equipment, metal products, automotive parts, project cargo, and bulk commodities. It supports both standard and specialized containers such as flat racks, open tops, and high-cube containers.

Q8. How do exporters decide between LCL and FCL sea freight? ▶

Exporters should evaluate cargo volume (CBM), weight and dimensions, shipment urgency, cargo value and sensitivity, budget, and frequency of exports. Consulting a freight forwarder or logistics expert helps exporters choose the most efficient and compliant sea freight solution.

Air Freight Services

Air freight is the fastest and most reliable mode of international logistics, specifically designed for time-critical, high-value, and precision engineering goods. In global trade, air freight plays a vital role in reducing lead time, preventing production downtime, and meeting urgent delivery commitments.

What is Air Freight?

Air freight refers to the transportation of goods through commercial passenger aircraft or dedicated cargo aircraft across international and domestic destinations. It is widely used for high-value, lightweight, fragile, or urgent shipments where speed, reliability, and security are top priorities.

Unlike sea freight, air freight focuses on time efficiency rather than volume, making it ideal for engineering components, electronics, aerospace parts, and emergency industrial supplies.

Key Characteristics of Air Freight

- Fastest mode of global transportation

- Airport-to-airport logistics network

- Advanced cargo tracking & security systems

- High compliance with international aviation standards

- Premium logistics solution for urgent exports

Why Use Air Freight for International Shipping?

Air freight is chosen when time sensitivity outweighs transportation cost. For engineering companies, delayed shipments can lead to production shutdowns, project delays, or financial penalties, making air freight a strategic choice.

Major Advantages of Air Freight

1. Fastest International Shipping Mode

Air freight drastically reduces transit time from weeks to days or even hours, enabling exporters to meet tight delivery schedules and emergency requirements.

2. Lower Inventory Holding Cost

Faster transit means less warehousing and storage, helping businesses reduce inventory carrying costs and working capital blockage.

3. High Cargo Security

Airports and airlines follow strict security protocols, minimizing risks of theft, damage, or cargo tampering, especially for high-value engineering products.

4. Reliability & Schedule Integrity

Airlines operate on fixed schedules, ensuring predictable and reliable delivery timelines.

5. Ideal for Emergency & Critical Shipments

- Production line breakdowns

- Urgent spare part requirements

- Critical project deadlines

Where is Air Freight Commonly Used?

Air freight is widely used across industries where speed, accuracy, and product integrity are essential.

Key Industries Using Air Freight

Aerospace & Aviation

- Aircraft components

- Avionics systems

- Precision aerospace parts

Electronics & Electrical Engineering

- Semiconductors

- Control panels

- Precision instruments

Industrial & Engineering Sector

- Critical machine spare parts

- CNC components

- Automation equipment

Project & Time-Bound Cargo

- Power plants

- Infrastructure projects

- Oil & gas shutdown support

Pharmaceutical & Medical Engineering

- Diagnostic equipment

- Medical devices

- Sensitive instruments

How Does Air Freight Work?

Air freight operates under strict international aviation regulations and follows a highly controlled logistics process to ensure speed, safety, and compliance.

1. Chargeable Weight Calculation

Air freight cost is calculated based on chargeable weight, which is the higher of:

- Actual weight (kg)

- Volumetric weight (L × W × H ÷ 6000)

This ensures efficient use of aircraft cargo space.

2. Specialized Packing Requirements

Air cargo requires lightweight, strong, and compliant packaging, often including:

- Shock-resistant packing

- Moisture protection

- UN-certified packaging (if applicable)

3. Regulatory & Safety Compliance

Air freight must comply with:

- IATA (International Air Transport Association) regulations

- ICAO safety standards

- Airline-specific cargo rules

- Dangerous Goods (DG) compliance, if applicable

4. Airport-to-Airport Transportation

Air freight primarily operates on an airport-to-airport basis, with optional door-to-door service through freight forwarders.

5. Customs Clearance & Delivery

- Export customs clearance at origin

- Airline handling & screening

- Import customs clearance at destination

- Final delivery to consignee

Air Freight vs Other Transport Modes (Quick Insight)

| Parameter | Air Freight | Sea Freight |

|---|---|---|

| Transit Time | Very Fast | Slow |

| Cost | High | Low |

| Cargo Type | High-value, urgent | Heavy, bulk |

| Security | Very High | Moderate |

| Ideal For | Time-critical | Cost-sensitive |

Types of Air Freight Services

A Detailed Export–Import Logistics Guide for Engineering & High-Value Cargo

Air freight services are a strategic component of global supply chain management, enabling exporters and importers to move time-critical, high-value, and precision cargo across international markets. Selecting the right type of air freight service is crucial for cost control, delivery performance, regulatory compliance, and customer satisfaction.

1. Express / Priority Air Freight Services

What is Express Air Freight?

Express air freight is a premium, time-definite air cargo service that ensures fastest possible international delivery, often within 24 to 72 hours. Shipments receive top priority status across airline booking, handling, and customs clearance processes.

Why Use Express Air Freight?

- Fastest international logistics solution

- Guaranteed cargo space and flight priority

- Minimizes production downtime and revenue loss

- Ideal for emergency and mission-critical shipments

- Reduced transit and handling risks

Where is Express Air Freight Used?

- Emergency engineering spare parts

- Aerospace and aviation components

- Critical electronics and automation parts

- Medical and life-saving equipment

- Urgent project cargo

How to Use Express Air Freight in Export / Import?

- Pre-booking with priority airline services

- Pre-approved export and import documentation

- Direct or minimum-connection flights

- Advance customs filing to avoid clearance delays

- Door-to-door express delivery where required

Real-Life Scenario: A manufacturing plant facing an unexpected machinery breakdown uses express air freight services to import a critical component overnight, preventing costly production stoppage.

2. Standard / General Air Freight Services

What is Standard Air Freight?

Standard air freight is the most widely used air cargo service, providing a balanced solution between speed and cost. Shipments move on scheduled commercial flights with reliable transit times.

Why Use Standard Air Freight?

- Cost-effective compared to express services

- Reliable airline schedules

- Suitable for planned international shipments

- Consistent delivery performance

- Ideal for routine export–import operations

Where is Standard Air Freight Used?

- Engineering components and assemblies

- Electrical and electronic goods

- Industrial equipment

- Finished manufacturing products

- Regular import and export cargo

How to Use Standard Air Freight in Export / Import?

- Advance cargo booking with airlines

- Standard packing and labeling

- Normal customs clearance timelines

- Airport-to-airport or door-to-door logistics

- Freight forwarder coordination

Real-Life Scenario: An exporter shipping precision-engineered components with a 7-day delivery commitment selects standard air freight to balance cost and delivery reliability.

3. Deferred / Economy Air Freight Services

What is Deferred Air Freight?

Deferred air freight is a budget-oriented air cargo service where shipments move on a space-available basis, resulting in longer but predictable transit times.

Why Use Deferred Air Freight?

- Lower air freight costs

- Suitable for non-urgent shipments

- Still faster than sea freight

- Effective for inventory replenishment

- Cost optimization for SMEs

Where is Deferred Air Freight Used?

- Non-critical engineering parts

- Backup spare parts inventory

- Promotional or marketing materials

- Low-priority imports

How to Use Deferred Air Freight in Export / Import?

- Flexible delivery scheduling

- Economy airline booking

- Indirect routing if required

- Standard export and import documentation

- Proper inventory planning

Real-Life Scenario: An importer restocking non-urgent machine spares uses deferred air freight to reduce logistics cost while maintaining acceptable lead time.

4. Charter Air Freight Services

What is Charter Air Freight?

Charter air freight involves exclusive use of an entire aircraft for a single shipment, providing maximum control over routing, scheduling, and cargo handling.

Why Use Charter Air Freight?

- Handles oversized and heavy cargo

- Custom departure and arrival schedules

- Direct point-to-point delivery

- Ideal for urgent project logistics

- Eliminates airline capacity constraints

Where is Charter Air Freight Used?

- Heavy engineering machinery

- Power plant and infrastructure projects

- Oil & gas equipment

- Humanitarian and disaster relief cargo

How to Use Charter Air Freight in Export / Import?

- Aircraft selection based on cargo specifications

- Custom flight planning and permissions

- Special loading and securing methods

- Dedicated customs and ground handling coordination

- End-to-end project management

Real-Life Scenario: A power sector company charters an aircraft to deliver oversized turbine components urgently to meet strict project deadlines.

5. Consolidated Air Freight Services

What is Consolidated Air Freight?

Consolidated air freight combines multiple shipments from different exporters into a single shipment to reduce individual freight costs.

Why Use Consolidated Air Freight?

- Lower freight cost per shipment

- Efficient for small and frequent exporters

- Optimized aircraft space utilization

- Reduced airline charges

Where is Consolidated Air Freight Used?

- Small engineering exporters

- SME international trade

- Spare parts shipments

- E-commerce and B2B exports

How to Use Consolidated Air Freight in Export / Import?

- Cargo delivered to consolidation warehouse

- Grouped under a master airway bill

- Shipped together on scheduled flights

- Deconsolidation and customs clearance at destination

Real-Life Scenario: Multiple exporters ship small quantities of machine components weekly using consolidated air freight to achieve cost efficiency.

6. Door-to-Door Air Freight Services

What is Door-to-Door Air Freight?

Door-to-door air freight is a comprehensive logistics solution where a single service provider manages pickup, air transport, customs clearance, and final delivery.

Why Use Door-to-Door Air Freight?

- End-to-end logistics management

- Single point of accountability

- Reduced coordination effort

- Ideal for first-time exporters and importers

- Transparent tracking and documentation

Where is Door-to-Door Air Freight Used?

- Prototype and sample exports

- SME and startup exporters

- Time-bound customer deliveries

- International B2B shipments

How to Use Door-to-Door Air Freight in Export / Import?

- Engage a freight forwarder

- Provide shipment and commercial documents

- Forwarder manages customs compliance

- Real-time shipment tracking

- Final delivery at consignee location

Real-Life Scenario: A first-time exporter ships engineering prototypes overseas using door-to-door air freight to avoid logistical complexity.

Choosing the Right Air Freight Service

| Business Condition | Best Air Freight Service |

|---|---|

| Emergency delivery | Express Air Freight |

| Planned urgent cargo | Standard Air Freight |

| Cost-sensitive shipment | Deferred Air Freight |

| Oversized project cargo | Charter Air Freight |

| Small frequent shipments | Consolidated Air Freight |

| New exporter/importer | Door-to-Door Air Freight |

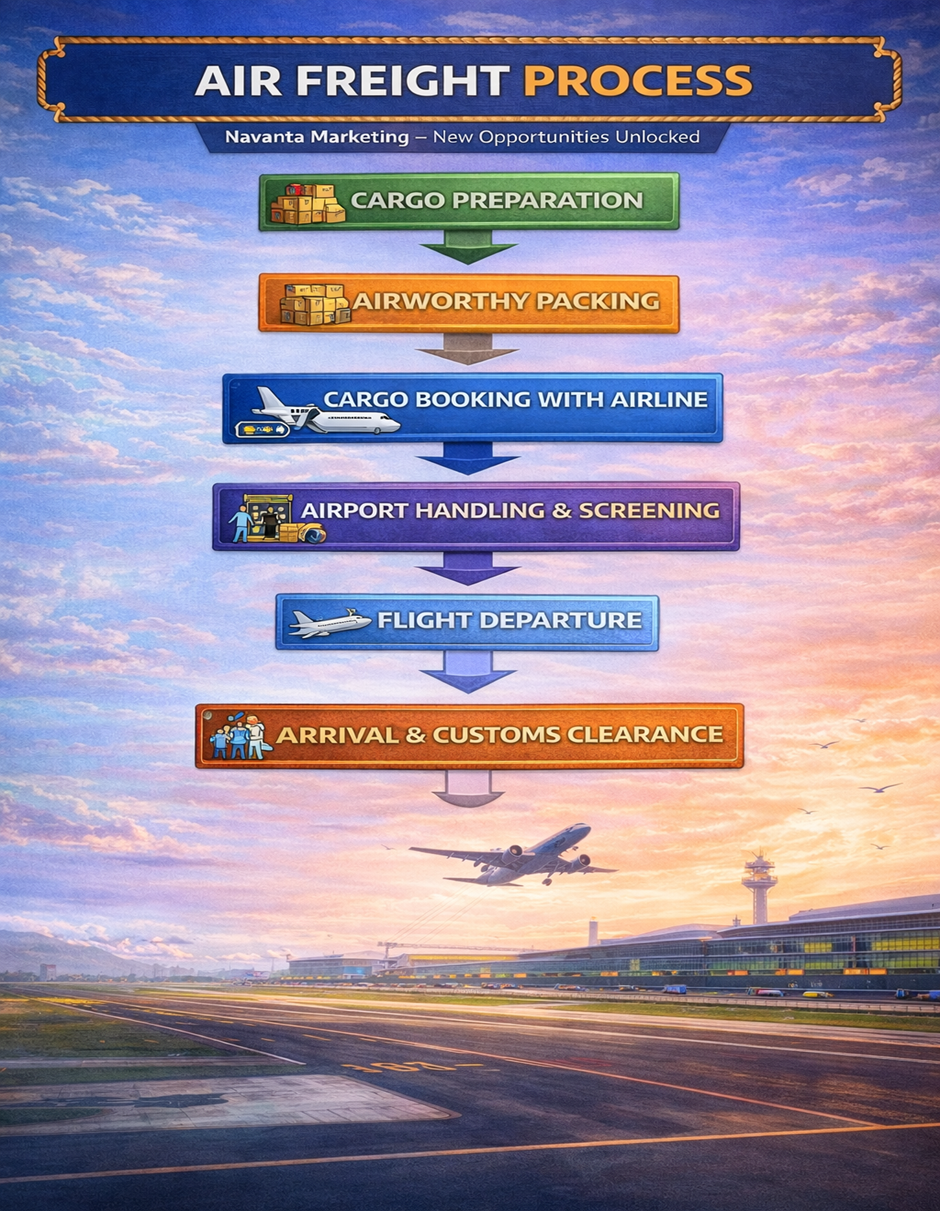

Air Freight Process Flowchart

Conclusion

Air freight is a strategic logistics solution for businesses that prioritize speed, reliability, and cargo safety over cost. For engineering exporters, aerospace suppliers, electronics manufacturers, and project-based industries, air freight ensures business continuity, customer satisfaction, and operational efficiency. Choosing the right air freight service provider and understanding chargeable weight, compliance, and packing standards helps businesses optimize cost while meeting urgent global demands.

FAQ – Air Freight Services

Q1. What are Air Freight Services in international trade? ▶

Air freight services refer to the transportation of cargo via commercial or dedicated cargo aircraft for domestic and international shipments. These services are mainly used for time-sensitive, high-value, and precision goods, including engineering components, electronics, aerospace parts, and urgent spare parts.

Q2. When should exporters or importers choose air freight? ▶

Air freight should be chosen when delivery speed, reliability, and cargo safety are more important than cost. It is ideal for urgent shipments, emergency imports, critical spare parts, prototypes, and high-value engineering goods where delays can cause production losses or project failure.

Q3. What types of goods are best suited for air freight services? ▶

Air freight is best suited for:

- Engineering & precision components

- Electronics and semiconductors

- Aerospace and aviation parts

- Medical and diagnostic equipment

- Critical machine spare parts

- Time-bound project cargo

These goods require fast transit, high security, and careful handling.

Q4. What are the main types of air freight services available? ▶

The common types of air freight services include:

- Express / Priority Air Freight

- Standard / General Air Freight

- Deferred / Economy Air Freight

- Consolidated Air Freight

- Charter Air Freight

- Door-to-Door Air Freight Services

Each type is designed to meet different urgency levels, cargo sizes, and cost requirements.

Q5. How is air freight cost calculated? ▶

Air freight charges are calculated based on chargeable weight, which is the higher of:

- Actual gross weight (kg)

- Volumetric weight (Length × Width × Height ÷ 6000)

This method ensures efficient use of aircraft cargo space.

Q6. Is air freight safe for high-value and fragile cargo? ▶

Yes, air freight is considered the safest mode of international transportation. Airports and airlines follow strict security checks, controlled handling procedures, and real-time tracking systems, making it ideal for high-value, fragile, and sensitive engineering goods.

Q7. What documents are required for air freight shipments? ▶

Common documents required for air freight include:

- Commercial Invoice

- Packing List

- Airway Bill (AWB)

- Export or Import Customs Documents

- Certificate of Origin (if applicable)

- DG Declaration (for dangerous goods)

Proper documentation ensures smooth customs clearance and on-time delivery.

Q8. What is the difference between air freight and sea freight? ▶

The key difference is speed vs cost:

- Air Freight: Fastest, high security, higher cost, ideal for urgent cargo

- Sea Freight: Cost-effective, suitable for heavy and bulk cargo, longer transit time

Exporters choose air freight when time is critical and sea freight when cost optimization is the priority.

Q9. Can air freight be used for door-to-door delivery? ▶

Yes, air freight can be provided as a door-to-door logistics service, where a freight forwarder manages pickup, air transportation, customs clearance, and final delivery. This option is highly suitable for SMEs, first-time exporters, and time-bound shipments.

Q10. How do exporters choose the right air freight service? ▶

Exporters should consider:

- Urgency of delivery

- Cargo value and sensitivity

- Shipment size and weight

- Budget and frequency of shipments

- Compliance and handling requirements

Consulting an experienced air freight forwarder helps in selecting the most efficient and cost-effective air freight service.

3. Rail & Multimodal Logistics

Advanced Guide for Exporters, Importers & Engineering Goods

Rail and multimodal logistics are becoming essential pillars of modern global trade, especially for engineering goods, bulk cargo, and long-distance shipments. These logistics solutions help businesses optimize cost, reduce risk, and improve supply chain efficiency by combining the strengths of multiple transport modes.

What is rail & multimodal logistics?

Rail Logistics

Rail logistics refers to the transportation of cargo using railway networks, primarily for long-distance inland movement of heavy, bulk, or containerized goods. Rail transport is widely used between manufacturing hubs, Inland Container Depots (ICDs), ports, and industrial corridors.

Multimodal Logistics

Multimodal logistics is the movement of goods using two or more modes of transport—such as road, rail, sea, and air—under a single transport contract and one logistics service provider.

In multimodal transport:

- One operator takes end-to-end responsibility

- Cargo moves seamlessly across modes

- Documentation is simplified

- Transit risk is reduced

Why use rail & multimodal logistics?

Rail and multimodal logistics are chosen to achieve cost efficiency, operational reliability, and sustainability, especially for engineering goods and industrial cargo.

Key Benefits of Rail Logistics

- Cost-effective for long-distance inland transport

- Ideal for heavy and bulk engineering goods

- High carrying capacity

- Lower fuel cost compared to road transport

Key Benefits of Multimodal Logistics

1. Cost Optimization

Combining transport modes helps select the most economical route, reducing overall freight and handling costs.

2. Reduced Transit Risk

A single logistics operator manages the entire movement, minimizing handover errors, delays, and cargo damage.

3. Better Inland Connectivity

Multimodal logistics efficiently connects factories, ICDs, ports, and final destinations, even in remote or landlocked regions.

4. Eco-Friendly Transportation

Rail and multimodal logistics significantly reduce carbon emissions, supporting sustainable and green supply chain practices.

Where is rail & multimodal logistics used?

Common Usage Locations

Inland Container Depots (ICDs)

- Movement of export/import containers between factories and ports

- Customs-bonded cargo handling

- Rail–road integration

Landlocked Countries & Regions

- Countries without direct sea access

- Dependence on rail and road links to nearest seaports

Long-Distance Domestic Transport

- Inter-state cargo movement

- Bulk raw materials and finished engineering goods

Industrial Corridors & Manufacturing Hubs

- Steel, automobile, heavy engineering clusters

- Power, infrastructure, and project cargo movement

How does multimodal transport work?

Multimodal logistics operates on coordination, documentation simplicity, and end-to-end responsibility.

Step-by-Step Multimodal Transport Process

1. Single Transport Contract

The shipper signs one multimodal transport agreement with a logistics service provider, even though multiple transport modes are involved.

2. One Logistics Service Provider

A Multimodal Transport Operator (MTO) or freight forwarder manages:

- Mode selection

- Scheduling

- Cargo handling

- Risk management

3. Single Transport Document

A Multimodal Transport Document (MTD) or combined transport document is issued, covering the entire journey.

4. Seamless Cargo Movement

- Factory → Road

- Road → Rail

- Rail → Port

- Port → Sea or Air

- Destination → Final delivery

5. Customs & Compliance Handling

- Customs documentation

- Regulatory compliance

- Coordination at ICDs and ports

Rail vs Multimodal Logistics (Quick Comparison)

| Aspect | Rail Logistics | Multimodal Logistics |

|---|---|---|

| Transport Modes | Rail only | Two or more modes |

| Contract | Mode-specific | Single contract |

| Flexibility | Moderate | High |

| Cost Efficiency | High for inland | High overall |

| Risk Management | Limited | Centralized |

| Ideal For | Inland bulk cargo | End-to-end global trade |

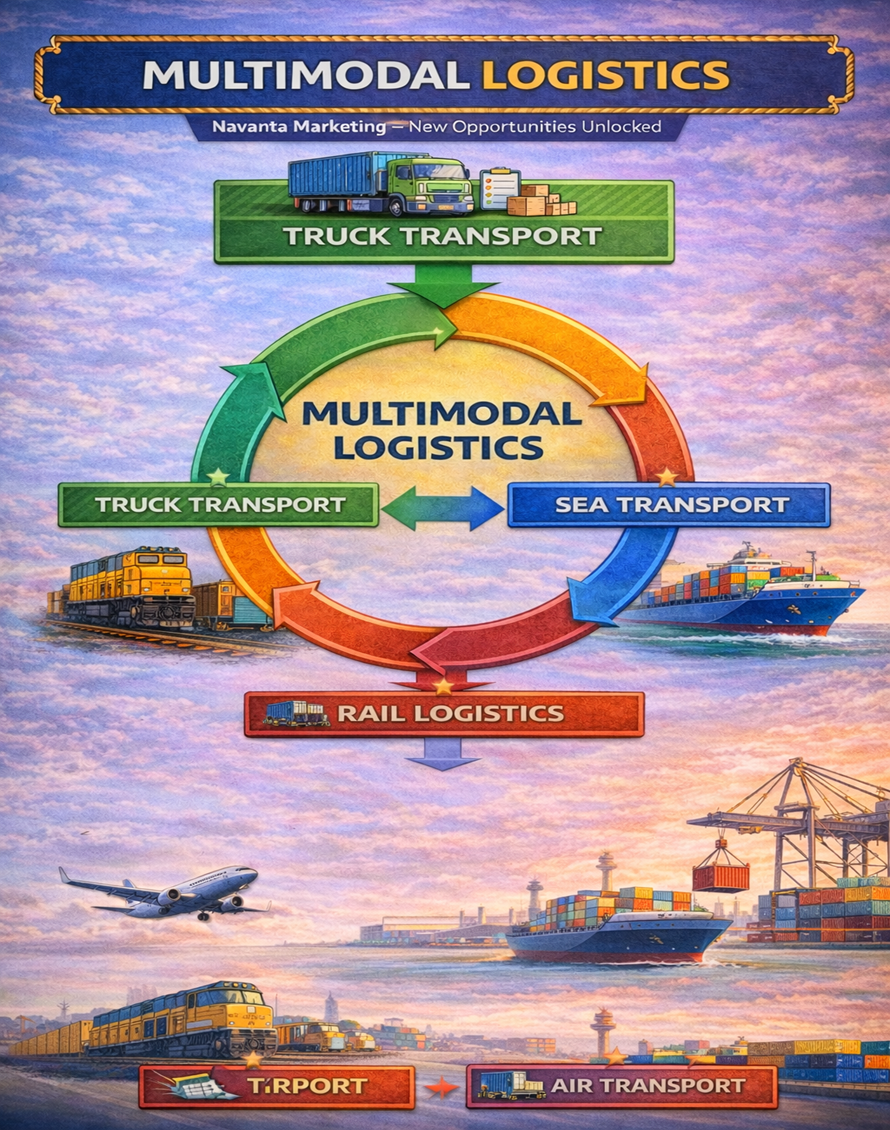

Multimodal Logistics

Conclusion

Rail & Multimodal Logistics provide a smart, cost-effective, and sustainable logistics solution for exporters and importers handling engineering goods, bulk cargo, and long-distance shipments. By combining rail efficiency with multimodal flexibility, businesses can achieve better transit control, reduced risk, and optimized logistics cost in both domestic and international trade.

FAQ – Rail & Multimodal Logistics

Q1. What is Rail & Multimodal Logistics? ▶

Rail & Multimodal Logistics refers to the transportation of goods using rail freight and two or more transport modes such as road, rail, sea, and air under a single logistics contract. It enables end-to-end cargo movement with better cost control, reduced risk, and improved supply chain efficiency.

Q2. What is the difference between Rail Logistics and Multimodal Logistics? ▶

Rail logistics uses only railway transport for inland cargo movement, whereas multimodal logistics integrates multiple transport modes under one operator. Multimodal logistics offers higher flexibility, simplified documentation, and centralized responsibility compared to standalone rail freight.

Q3. Why should exporters and importers use Multimodal Logistics? ▶

Exporters and importers use multimodal logistics to reduce transportation cost, minimize transit delays, and ensure seamless cargo flow across borders. It is especially beneficial for engineering goods, project cargo, and long-distance international trade.

Q4. When is Rail Freight the best logistics option? ▶

Rail freight is ideal when:

- Cargo is heavy, bulky, or containerized

- Distance is long and inland

- Cost efficiency is a priority

- Cargo movement is between ICDs, ports, and industrial corridors

Q5. What types of cargo are suitable for Rail & Multimodal Logistics? ▶

Rail & multimodal logistics are suitable for:

- Engineering goods

- Machinery and equipment

- Steel and metal products

- Automobile components

- Bulk raw materials

- Project and infrastructure cargo

Q6. How does documentation work in Multimodal Logistics? ▶

In multimodal logistics, a single transport document such as a Multimodal Transport Document (MTD) is issued. This document covers the entire journey, reducing paperwork, simplifying customs clearance, and ensuring single-point liability.

Q7. Is Multimodal Logistics safe for international trade? ▶

Yes, multimodal logistics is highly secure because one logistics operator manages the entire supply chain. This reduces cargo handling risks, transit damage, miscommunication, and delays, making it reliable for international exports and imports.

Q8. How does Rail & Multimodal Logistics reduce logistics costs? ▶

Costs are reduced by:

- Using rail for long-distance inland transport

- Optimizing routes and modes

- Lower fuel consumption

- Reduced handling and storage charges

- Efficient container utilization

Q9. Where are Rail & Multimodal Logistics commonly used? ▶

They are widely used in:

- Inland Container Depots (ICDs)

- Landlocked countries

- Industrial corridors

- Export hubs and manufacturing zones

- Long-distance domestic and international routes

Q10. Who manages the shipment in Multimodal Logistics? ▶

A Multimodal Transport Operator (MTO) or integrated logistics provider manages the entire shipment, taking responsibility for transport coordination, documentation, customs support, and cargo delivery from origin to destination.

4. Container Types for Engineering Goods

Complete Guide for Exporters, Importers & Project Cargo

Choosing the right container type is a critical decision in global logistics, especially for engineering goods, machinery, industrial equipment, and project cargo. Proper container selection ensures cargo safety, cost efficiency, regulatory compliance, and smooth international transportation.

What are container types?

Container types are standardized steel transport units designed to safely carry different kinds of cargo across sea, rail, road, and multimodal logistics networks. Each container type is engineered to handle specific cargo dimensions, weight, handling requirements, and environmental conditions.

For engineering goods, container selection depends on:

- Cargo size and weight

- Shape and height

- Sensitivity (temperature, moisture)

- Handling and loading method

Why is container selection important?

1. Prevents Cargo Damage

Engineering goods are often heavy, precision-based, and high-value. Using the right container prevents:

- Structural stress

- Transit damage

- Improper securing

2. Optimizes Freight Cost

Incorrect container choice can lead to:

- Space wastage

- Higher freight rates

- Re-handling charges

Optimized container selection improves container utilization and cost efficiency.

3. Ensures Regulatory Compliance

Different cargo types must comply with:

- IMO regulations

- ISO container standards

- Port and shipping line rules

Correct container selection avoids customs delays and penalties.

4. Supports Oversized & Project Cargo

Engineering goods often exceed standard dimensions. Specialized containers support:

- Over-height cargo

- Over-width machinery

- Heavy lift equipment

Where are containers used?

Key Usage Locations

Ports

- Container loading and unloading

- Sea freight transport

- Customs clearance

Inland Container Depots (ICDs)

- Stuffing and de-stuffing

- Customs-bonded cargo handling

- Rail–road connectivity

Manufacturing Plants

- Factory stuffing

- Export-ready cargo movement

Project Cargo Sites

- Infrastructure projects

- Power plants

- Construction and industrial installations

How to select the right container for engineering goods?

Container selection depends on cargo characteristics and logistics constraints.

Key evaluation factors:

- Cargo dimensions (length, width, height)

- Cargo weight

- Loading method (crane, forklift)

- Sensitivity (temperature, moisture)

- Regulatory requirements

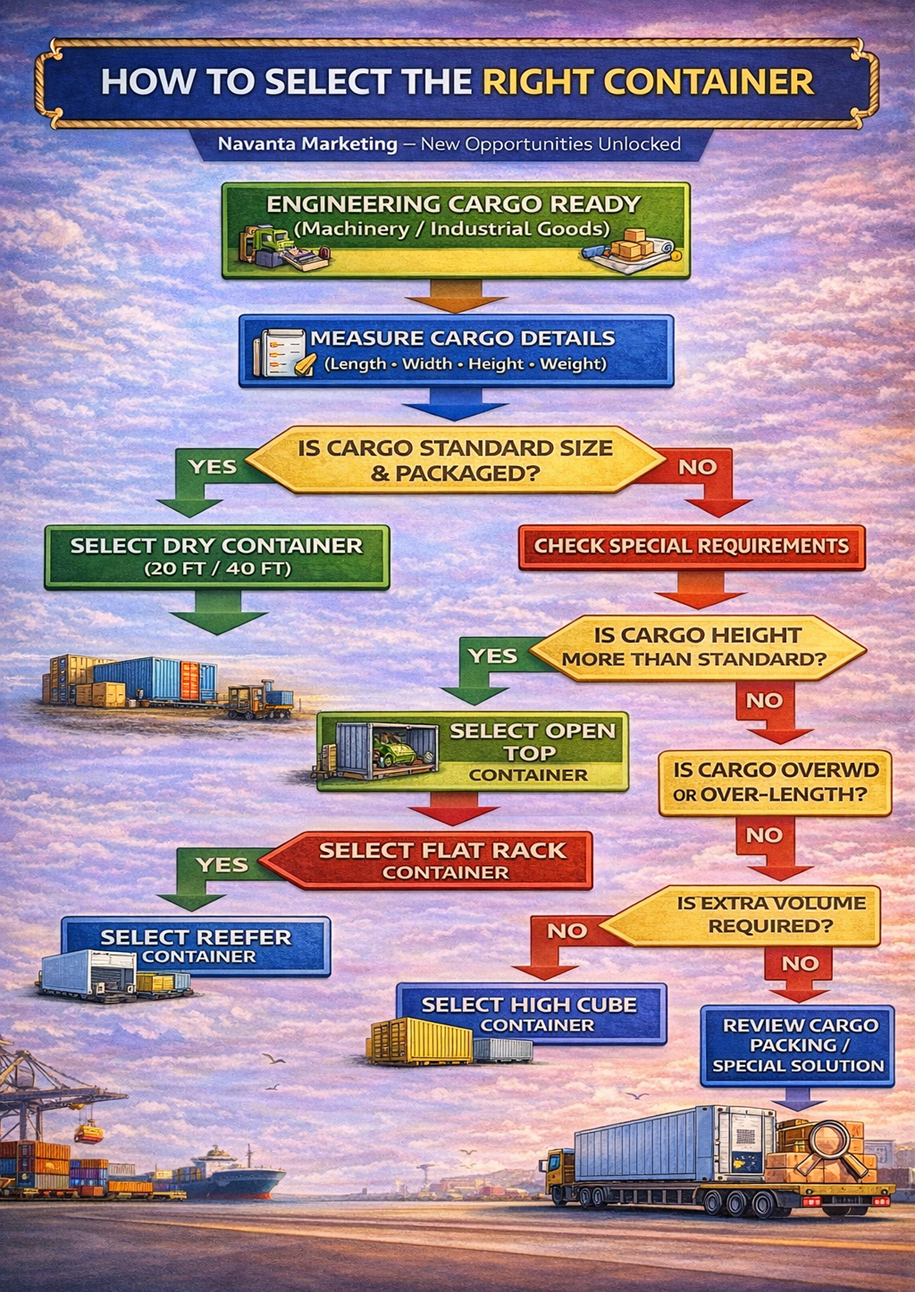

How to select the right container

Conclusion

Selecting the right container type for engineering goods is essential for safe cargo movement, optimized logistics cost, and regulatory compliance. From standard dry containers to flat racks, open tops, reefers, ISO tanks, and high cube containers, each container serves a specific industrial logistics requirement. Proper container planning ensures damage-free delivery, smoother customs clearance, and efficient global trade operations.

FAQ – Container Types for Engineering Goods

Q1. What are container types in international logistics? ▶

Container types are standardized steel units used to transport goods safely via sea, rail, road, and multimodal logistics. Different container types are designed to handle varied cargo sizes, weights, shapes, and handling requirements, especially for engineering and industrial goods.

Q2. Why is choosing the right container type important? ▶

Selecting the correct container type helps to prevent cargo damage, optimize freight costs, ensure regulatory compliance, and support oversized or heavy machinery. Incorrect container selection can result in higher shipping costs, cargo damage, and customs delays.

Q3. Which container is best for general engineering goods? ▶

A Dry Container (20 ft or 40 ft) is best for standard-sized, palletized, or boxed engineering goods such as spare parts, tools, and machinery components. It offers maximum protection and cost efficiency for regular cargo.

Q4. What container should be used for heavy or oversized machinery? ▶

A Flat Rack Container is ideal for heavy, over-width, or over-length engineering equipment. It allows top and side loading, making it suitable for construction machinery, transformers, and large industrial units.

Q5. When should an Open Top container be used? ▶

An Open Top Container is used when cargo exceeds standard container height and requires top loading by crane. It is commonly used for tall machinery, industrial presses, and vertical equipment.

Q6. What is a High Cube container and when is it required? ▶

A High Cube Container is similar to a standard container but offers extra height (approximately 1 foot more). It is ideal for lightweight but voluminous engineering goods that require additional vertical space without using specialized containers.

Q7. Which container is suitable for temperature-sensitive engineering goods? ▶

A Reefer Container is used for temperature-controlled transportation. It is suitable for industrial chemicals, electronic components, and sensitive engineering materials that require a controlled environment during transit.

Q8. What is an ISO Tank container used for? ▶

An ISO Tank Container is designed to transport liquid chemicals, industrial oils, and hazardous or non-hazardous liquids safely. It complies with international safety and quality standards.

Q9. Where are containers for engineering goods commonly used? ▶

Containers are widely used at manufacturing plants, Inland Container Depots (ICDs), ports, industrial corridors, and project cargo sites for both export and import operations.

Q10. How can exporters and importers ensure correct container selection? ▶

Exporters and importers should evaluate:

- Cargo dimensions and weight

- Loading and unloading method

- Temperature or safety requirements

- Destination regulations

Consulting a freight forwarder or logistics expert ensures optimal container utilization and risk-free transportation.

5. Logistics Cost Optimization

Advanced Cost Control Strategy for Exporters & Importers

Logistics Cost Optimization is one of the most powerful profit-improvement tools in global trade. By optimizing freight, warehousing, handling, documentation, and customs costs, businesses can achieve higher margins, competitive pricing, and sustainable supply chain operations—without compromising service quality or cargo safety.

What is logistics cost optimization?

Logistics Cost Optimization is the systematic reduction of transportation and supply chain expenses while maintaining or improving delivery speed, reliability, and cargo safety. It focuses on eliminating inefficiencies, improving resource utilization, and selecting the most cost-effective logistics strategies.

Optimization does not mean cost cutting at risk—it means smart planning, data-driven decisions, and operational efficiency.

Why is logistics cost optimization critical?

1. Improves Profit Margin

Logistics costs typically account for 10–20% of product value. Even a 5–10% reduction directly increases net profit without increasing sales.

2. Enables Competitive Pricing

Lower logistics costs allow exporters and importers to:

- Offer better CIF / DDP pricing

- Win international tenders

- Compete in price-sensitive markets

3. Supports Sustainable Operations

Optimized logistics reduces:

- Fuel consumption

- Carbon emissions

- Wasteful handling and storage

4. Improves Cash Flow

Lower freight and inventory costs reduce working capital blockage and inventory holding expenses.

Where do logistics costs arise?

Logistics costs are spread across the entire supply chain, not just transportation.

Major Cost Components

1. Freight Charges

- Sea freight (LCL / FCL)

- Air freight

- Rail and road transport

- Fuel surcharges

2. Port & Terminal Handling Charges

- THC (Terminal Handling Charges)

- CFS / ICD handling

- Equipment usage

3. Warehousing Costs

- Storage rent

- Inventory holding cost

- Handling and palletization

4. Documentation & Compliance

- Freight forwarder fees

- Customs documentation

- Certification and inspection charges

5. Customs Duties & Taxes

- Basic customs duty

- IGST / VAT

- Anti-dumping or safeguard duties

How to optimize logistics cost? (Strategic & practical)

1. Mode Selection Optimization (Sea vs Air vs Rail)

Choosing the right transport mode has the largest cost impact.

| Mode | Cost | Transit Time | Best Use |

|---|---|---|---|

| Sea Freight | Lowest | Slow | Bulk & heavy goods |

| Air Freight | Highest | Fastest | Urgent, high-value cargo |

| Rail Freight | Medium | Moderate | Inland long-distance |

Optimization Tip: Use sea freight for planned shipments and air freight only for emergencies.

2. Load & Container Optimization

Poor container utilization increases cost per unit.

Key Actions:

- Optimize carton dimensions

- Improve pallet stacking

- Choose correct container type

- Avoid shipping “air” inside containers

3. Route & Transit Planning

Indirect routes and unnecessary transshipment increase:

- Freight cost

- Transit risk

- Insurance premium

Optimization Strategies:

- Use direct sailings

- Avoid congestion-prone ports

- Select optimized rail corridors

4. Freight Rate Negotiation

Long-term and volume-based contracts reduce rates.

Best Practices:

- Annual freight contracts

- Multi-shipment agreements

- Rate benchmarking

5. Consolidation Strategies

LCL to FCL Conversion Combining multiple small shipments into one FCL drastically reduces cost.

EXACT CALCULATION – Logistics Cost Optimization (Real Example)

Example Scenario: Exporter shipping Engineering Goods (10 CBM, 6,000 kg) from India to Germany

Option 1: LCL Shipment (Before Optimization)

| Cost Component | Amount (USD) |

|---|---|

| LCL Freight | 1,200 |

| Origin Handling | 300 |

| Destination CFS | 350 |

| Documentation | 150 |

| Total Logistics Cost | 2,000 USD |

Option 2: Optimized FCL Shipment (After Optimization)

| Cost Component | Amount (USD) |

|---|---|

| 20 ft FCL Freight | 1,400 |

| Origin Handling | 250 |

| Destination Handling | 250 |

| Documentation | 100 |

| Total Logistics Cost | 2,000 USD |

BUT Cargo Volume Utilization:

- LCL cost per CBM = 200 USD

- FCL cost per CBM (full utilization) = 140 USD

| Item | LCL | FCL |

|---|---|---|

| Total Cost | 2,800 USD | 1,400 USD |

| Cost per CBM | 200 USD | 100 USD |

| Savings | – | 50% |

| Logistics Cost Optimization Formula |

|---|

|

Logistics Cost per Unit = (Total Freight + Handling + Documentation + Warehousing) ÷ Total Cargo Volume or Weight |

Key KPIs to Track Logistics Cost Optimization

- Freight cost per CBM / MT

- Logistics cost as % of sales

- Inventory holding cost

- Transit time variance

- Damage and claim ratio

Logistics Cost Optimization Process

Conclusion

Logistics Cost Optimization is a strategic advantage, not just a cost-saving exercise. By optimizing mode selection, container utilization, route planning, freight negotiation, and consolidation strategies, exporters and importers can achieve lower logistics cost, higher margins, faster deliveries, and sustainable global operations.

FAQ – Logistics Cost Optimization

Q1. What is Logistics Cost Optimization? ▶

Logistics Cost Optimization is the strategic process of reducing transportation and supply chain costs without compromising delivery timelines, cargo safety, or service quality. It focuses on improving freight efficiency, container utilization, route planning, and operational control.

Q2. Why is logistics cost optimization important for exporters and importers? ▶

Logistics costs directly impact profit margins and product competitiveness. Optimizing logistics expenses helps exporters and importers offer better pricing, improve cash flow, and stay competitive in global markets while maintaining reliable delivery performance.

Q3. What are the major cost components in logistics? ▶

The main logistics cost components include:

- Freight charges (sea, air, rail, road)

- Port and terminal handling charges

- Warehousing and inventory holding costs

- Documentation and compliance fees

- Customs duties and taxes

Q4. How does mode selection help in optimizing logistics costs? ▶

Selecting the right transportation mode significantly reduces costs. Sea freight is ideal for heavy and bulk cargo, air freight for urgent and high-value shipments, and rail freight for cost-effective inland movement. Correct mode selection avoids unnecessary premium charges.

Q5. How does container and load optimization reduce logistics cost? ▶

Proper container and load optimization ensures maximum space utilization, reducing the cost per unit shipped. Choosing the right container type and improving packing efficiency prevents space wastage and avoids higher freight and handling charges.

Q6. What role does cargo consolidation play in cost optimization? ▶

Cargo consolidation combines multiple smaller shipments into a single larger shipment, such as converting LCL to FCL. This significantly reduces freight cost per CBM, handling charges, and documentation expenses.

Q7. Can route planning reduce logistics costs? ▶

Yes, optimized route planning reduces transit time, fuel costs, port congestion delays, and risk of cargo damage. Choosing direct routes and efficient corridors leads to lower overall logistics expenses.

Q8. How do freight rate negotiations help in cost optimization? ▶

Negotiating freight rates through long-term contracts, volume commitments, and rate benchmarking helps secure lower rates from shipping lines and logistics providers, resulting in consistent cost savings.

Q9. How can documentation and compliance impact logistics costs? ▶

Errors in documentation or regulatory non-compliance can lead to shipment delays, demurrage, detention, and penalties. Streamlined documentation and proper compliance reduce hidden logistics costs and avoid unnecessary expenses.

Q10. How can companies measure logistics cost optimization success? ▶

Success can be measured by tracking key performance indicators such as:

- Logistics cost per unit (CBM or MT)

- Logistics cost as a percentage of sales

- Transit time consistency

- Inventory holding cost

- Damage and claim ratio

6. Freight Forwarder vs NVOCC vs CHA

In international trade and global logistics, Freight Forwarders, NVOCCs, and CHAs play distinct but interconnected roles. Understanding their differences helps exporters and importers select the right logistics partner, ensure legal compliance, control costs, and achieve smooth shipment execution.

What are these entities?

Freight Forwarder

A Freight Forwarder is a logistics professional or company that organizes and manages the complete movement of cargo from origin to destination. Freight forwarders act as logistics coordinators, handling transport planning, documentation, and communication across the supply chain.

NVOCC (Non-Vessel Operating Common Carrier)

An NVOCC is a logistics entity that does not own vessels but issues its own House Bill of Lading and contracts directly with shipping lines. NVOCCs specialize in sea freight consolidation and container space management.

CHA (Customs House Agent)

A Customs House Agent (CHA) is a licensed professional authorized by customs authorities to handle customs clearance, duty payment, and regulatory compliance for import and export cargo.

Why understanding these differences is important?

1. Correct Partner Selection

Each entity serves a specific logistics function. Selecting the right partner ensures operational efficiency and regulatory compliance.

2. Legal & Regulatory Compliance

Customs laws require licensed CHAs for clearance, while shipping requires authorized NVOCCs or forwarders.

3. Cost Control & Transparency

Understanding roles prevents duplicate charges, hidden costs, and misaligned responsibilities.

4. Smooth Shipment Execution

Clear role definition avoids delays, documentation errors, and coordination failures.

Where each entity is used?

Freight Forwarder

- Global export & import shipments

- Multimodal logistics (road, rail, sea, air)

- End-to-end supply chain management

NVOCC

- Sea freight shipments

- LCL and FCL consolidation

- Issuance of House Bill of Lading

CHA

- Ports, ICDs, airports

- Customs clearance zones

- Bonded warehouses

Roles & responsibilities

1. Freight Forwarder – Roles & Responsibilities

Core Responsibilities:

- Shipment planning and coordination

- Mode selection (sea, air, rail, road)

- Freight rate negotiation

- Booking cargo space

- Documentation handling

- Cargo tracking and delivery coordination

Acts As:

- Single point of contact for shippers

- Logistics consultant and coordinator

- Risk management partner

Best Used When:

- Shipper needs end-to-end logistics management

- Multiple transport modes are involved

- International coordination is required

2. NVOCC – Roles & Responsibilities

Core Responsibilities:

- Booking vessel space from shipping lines

- Issuing House Bill of Lading (HBL)

- Consolidating LCL cargo

- Managing container utilization

- Handling port-to-port sea freight

Acts As:

- Carrier to the shipper

- Shipper to the shipping line

Best Used When:

- LCL shipments require consolidation

- Cost-effective sea freight is needed

- House Bill of Lading issuance is preferred

3. CHA – Roles & Responsibilities

Core Responsibilities:

- Filing shipping bills and bills of entry

- HS code classification

- Duty and tax calculation

- Customs examination coordination

- Regulatory compliance and approvals

Acts As:

- Legal representative before customs authorities

- Compliance and documentation expert

Best Used When:

- Import or export customs clearance is required

- Regulatory documentation is complex

- Cargo requires inspection or certification

How do freight forwarder, NVOCC & CHA work together?

Integrated Workflow Example:

- Exporter appoints a Freight Forwarder → Plans shipment, selects route and mode

- Forwarder engages an NVOCC → NVOCC books vessel space and issues HBL

- CHA handles customs clearance → Files documents, pays duties, clears cargo

- Cargo moves smoothly to destination → Final delivery coordinated by forwarder

This collaboration ensures:

- Compliance with customs regulations

- Efficient cargo movement

- Cost-effective shipping

- Reduced risk of delays

Freight Forwarder vs NVOCC vs CHA – Comparison Table

| Aspect | Freight Forwarder | NVOCC | CHA |

|---|---|---|---|

| Primary Role | Logistics management | Sea freight carrier | Customs clearance |

| Bill of Lading | May issue | Issues own HBL | Does not issue |

| Licensing | Trade/Logistics | Shipping authority | Customs authority |

| Customs Handling | Coordinates | No | Yes |

| Mode Coverage | All modes | Sea only | Customs only |

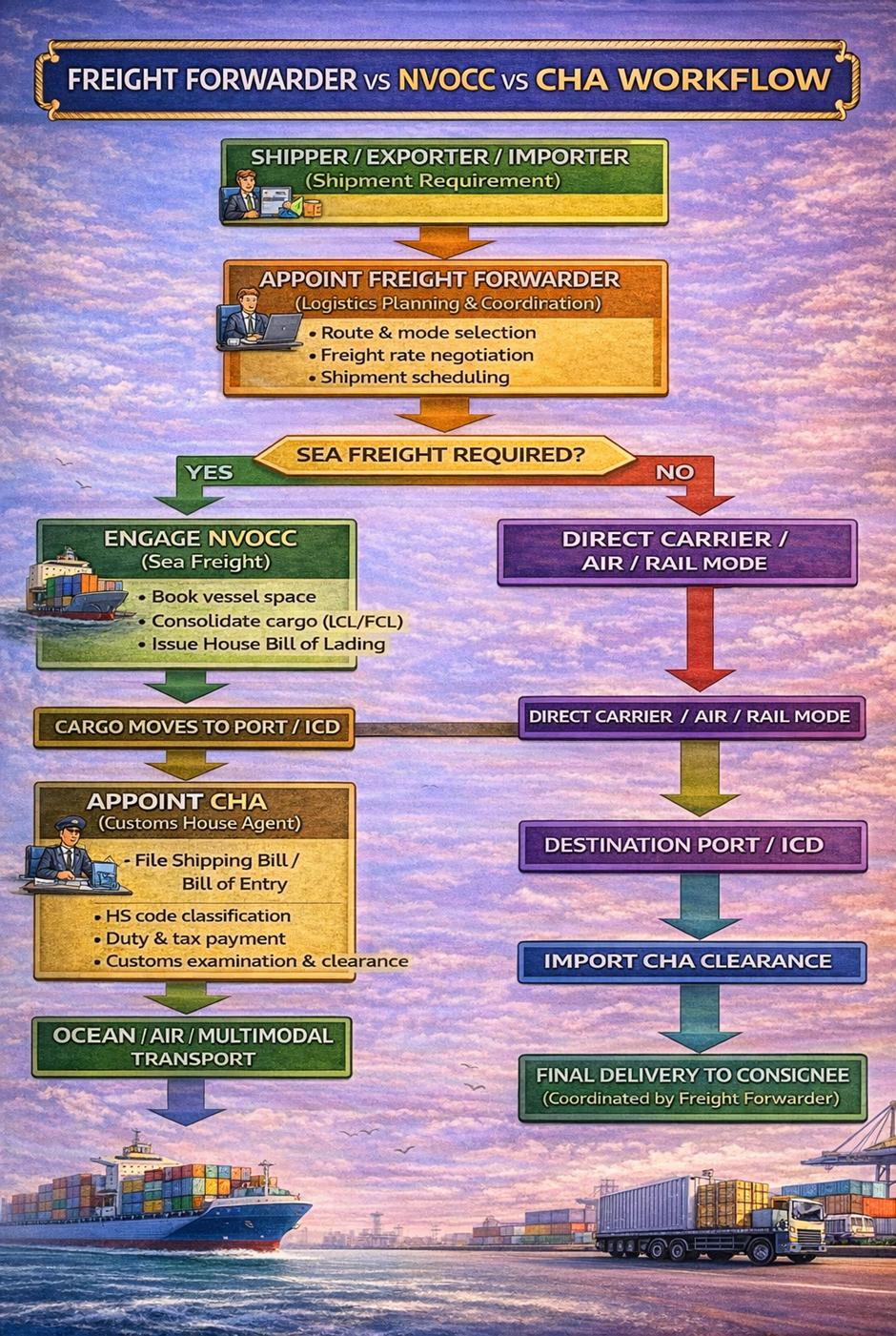

Freight Forwarder vs NVOCC vs CHA Workflow

Conclusion

Understanding the difference between a Freight Forwarder, NVOCC, and CHA is critical for successful export-import operations. While a freight forwarder manages the complete logistics journey, an NVOCC specializes in sea freight and container consolidation, and a CHA ensures customs compliance and clearance. Together, they form a strong logistics ecosystem that enables cost-effective, compliant, and smooth global trade.

FAQ – Freight Forwarder, NVOCC & CHA

Q1. What is a Freight Forwarder? ▶

A Freight Forwarder is a logistics service provider that manages end-to-end cargo movement from origin to destination. Freight forwarders coordinate transport planning, freight booking, documentation, tracking, and delivery across sea, air, rail, and road modes.

Q2. What is an NVOCC? ▶

An NVOCC (Non-Vessel Operating Common Carrier) is a logistics entity that does not own ships but books vessel space from shipping lines and issues its own House Bill of Lading (HBL). NVOCCs mainly handle sea freight consolidation and container management.

Q3. What is a CHA (Customs House Agent)? ▶

A Customs House Agent (CHA) is a government-licensed professional authorized to handle customs clearance procedures on behalf of exporters and importers. CHAs ensure compliance with customs laws, duty payment, and cargo examination.

Q4. What is the main difference between a Freight Forwarder, NVOCC, and CHA? ▶

- Freight Forwarder: Manages overall logistics coordination

- NVOCC: Acts as a sea freight carrier and issues HBL

- CHA: Handles customs clearance and regulatory compliance

Each plays a distinct role in international trade.

Q5. When should an exporter or importer use a Freight Forwarder? ▶

A freight forwarder should be used when end-to-end logistics management is required, especially for international shipments involving multiple transport modes or destinations.

Q6. When is an NVOCC required? ▶

An NVOCC is required when shipping by sea freight, particularly for:

- LCL (Less than Container Load) shipments

- Cost-effective container consolidation

- Issuance of a House Bill of Lading

Q7. Is a CHA mandatory for customs clearance? ▶

Yes, in most countries (including India), customs clearance must be handled by a licensed CHA. They are legally authorized to file shipping bills, bills of entry, and represent clients before customs authorities.

Q8. Can one company act as Freight Forwarder, NVOCC, and CHA? ▶

Yes, some logistics companies are licensed to act as freight forwarder, NVOCC, and CHA. This provides single-window logistics solutions, better coordination, and reduced cost and documentation complexity.

Q9. Who is legally responsible for the cargo during sea transport? ▶

When an NVOCC issues a House Bill of Lading, the NVOCC acts as the carrier and holds responsibility towards the shipper. The shipping line remains responsible under the Master Bill of Lading.

Q10. How do Freight Forwarder, NVOCC, and CHA work together? ▶

A freight forwarder plans and coordinates the shipment, an NVOCC manages sea freight and issues the House Bill of Lading, and a CHA ensures customs clearance. Together, they enable smooth, compliant, and cost-effective global cargo movement.

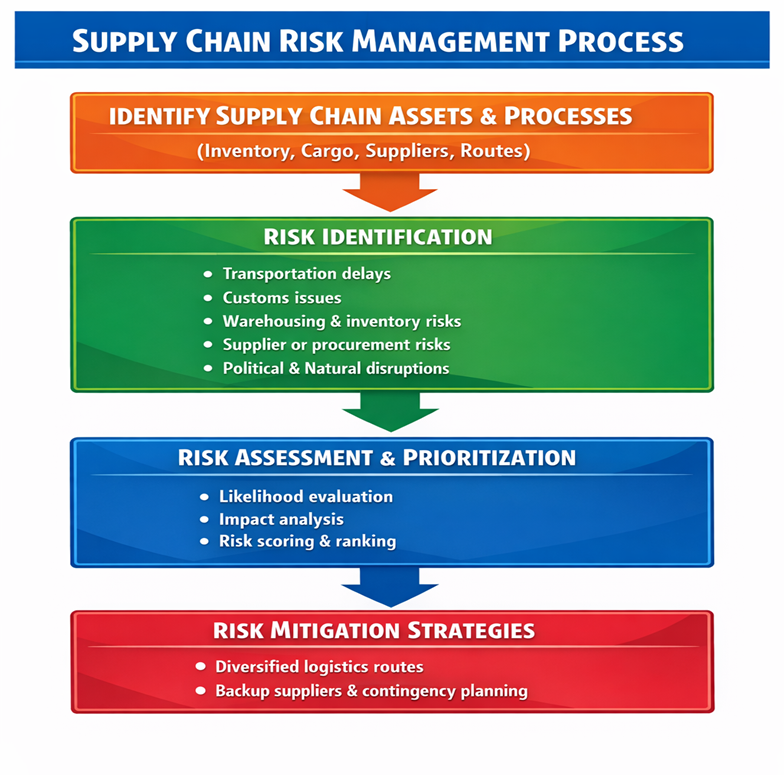

7. Supply Chain Risk Management

Complete Guide for Exporters, Importers & Industrial Logistics

Supply Chain Risk Management (SCRM) is a strategic approach to identify, assess, and mitigate risks that can disrupt the movement of goods, materials, and information across the global supply chain. Effective SCRM ensures business continuity, cargo safety, timely delivery, and cost efficiency, which are critical for engineering, industrial, and project-based shipments.

What is supply chain risk management?

Supply Chain Risk Management is the process of identifying potential risks in the supply chain, analyzing their impact, and implementing mitigation strategies. Risks can occur at any point in the supply chain, including transportation, warehousing, procurement, and customs operations.

Key Features:

- Proactive risk assessment

- Real-time monitoring and reporting

- Contingency planning for disruptions

- Coordination across suppliers, carriers, and logistics partners

Why is supply chain risk management important?

1. Prevents Delays

Timely identification of risks like port congestion, customs inspections, or transport breakdowns helps prevent shipment delays, ensuring on-time delivery.

2. Protects Cargo Value

High-value engineering goods, machinery, and industrial equipment are vulnerable to damage, theft, or environmental hazards. SCRM ensures insurance coverage, proper packaging, and handling protocols.

3. Ensures Business Continuity

Supply chain disruptions can halt production or project execution. Risk management ensures backup suppliers, alternative transport routes, and emergency protocols are in place.

4. Reduces Financial Loss

By anticipating and mitigating risks, companies can avoid penalty charges, demurrage, inventory losses, and additional freight costs.

5. Improves Stakeholder Confidence

Customers, investors, and partners gain trust in consistent delivery performance and risk-aware operations.

Where do supply chain risks occur?

1. Transportation Risks

- Vessel or truck delays

- Accidents or cargo damage

- Carrier insolvency

2. Customs & Regulatory Risks

- Delays in clearance

- Non-compliance penalties

- Changing regulations

3. Warehousing & Inventory Risks

- Fire, theft, or spoilage

- Mismanagement or overstocking

- Equipment failure

4. Supplier & Procurement Risks

- Single-source dependency

- Quality or production delays

- Price volatility

5. Political & Natural Risks

- Strikes, protests, or political instability

- Floods, earthquakes, or pandemics

- Trade restrictions or embargoes

How to manage supply chain risks?

1. Diversified Logistics Routes

- Use multiple transport modes (sea, air, rail, road)

- Avoid single-route dependency

- Plan alternate ports and inland hubs

2. Cargo Insurance

- Marine cargo insurance for ocean freight

- Air cargo insurance for high-value goods

- Coverage for natural disasters, theft, or damage

3. Backup Suppliers & Contingency Planning

- Maintain alternative suppliers

- Maintain safety stock or buffer inventory

- Include emergency procurement contracts

4. Compliance Audits & Documentation

- Regular supplier and logistics audits

- Ensure customs, safety, and environmental compliance

- Maintain updated certificates and permits

5. Real-Time Tracking & Monitoring

- GPS and IoT-enabled cargo tracking

- Shipment monitoring dashboards

- Early warning alerts for delays, temperature deviation, or route disruption

6. Risk Assessment & KPI Monitoring

- Perform risk scoring for all supply chain nodes

- Monitor key performance indicators (on-time delivery, damage ratio, insurance claims)

- Continuously refine mitigation strategies

Benefits of effective supply chain risk management

- Reduced shipment delays and disruptions

- Minimized cargo damage or loss

- Lower financial and operational impact from unforeseen events

- Better supplier and carrier reliability

- Enhanced global trade reputation and customer satisfaction

Supply Chain Risk Management Process

FAQ – Supply Chain Risk Management

Q1. What is Supply Chain Risk Management (SCRM)? ▶

Supply Chain Risk Management is the process of identifying, analyzing, and mitigating risks in the supply chain to ensure timely delivery, cargo safety, and business continuity. It covers all stages including transportation, warehousing, customs, and supplier operations.

Q2. Why is Supply Chain Risk Management important? ▶

SCRM is critical because it:

- Prevents shipment delays

- Protects cargo value and reduces damage

- Ensures business continuity

- Minimizes financial loss

- Enhances stakeholder confidence

Q3. Where do supply chain risks commonly occur? ▶

Supply chain risks can occur in:

- Transportation (delays, accidents, carrier failure)

- Customs and regulatory compliance (clearance delays, penalties)

- Warehousing and inventory (damage, theft, spoilage)

- Supplier & procurement (single-source dependency, production delays)

- Political & natural disruptions (strikes, floods, trade restrictions)

Q4. How can logistics companies or exporters manage supply chain risks? ▶

Risks can be managed by:

- Using diversified logistics routes and alternative transport modes

- Procuring cargo insurance (sea, air, rail)

- Maintaining backup suppliers and contingency plans

- Conducting compliance audits and documentation checks

- Implementing real-time tracking for shipments

- Monitoring risk KPIs (on-time delivery, damage ratio, claims)

Q5. What is the role of cargo insurance in risk management? ▶

Cargo insurance protects shipments against damage, theft, or loss during transit. It ensures that high-value engineering goods, industrial equipment, or project cargo are financially secured in case of unforeseen events.

Q6. How do backup suppliers help in mitigating risks? ▶

Backup suppliers reduce dependency on a single source, ensuring continuity if the primary supplier fails due to production issues, strikes, or natural disasters. This reduces the risk of project delays and production halts.

Q7. What is the importance of real-time tracking in risk management? ▶

Real-time tracking allows monitoring of shipment location, transit conditions, and deviations. Early alerts help in proactive decision-making, rerouting, or corrective action to avoid delays or cargo damage.

Q8. How can companies assess and prioritize supply chain risks? ▶

Companies can use risk scoring and ranking methods to evaluate the likelihood and impact of potential disruptions. High-impact, high-probability risks are prioritized for mitigation planning.

Q9. Can technology help in Supply Chain Risk Management? ▶

Yes, technologies such as IoT sensors, GPS tracking, AI-based risk analytics, and logistics dashboards provide real-time data and predictive insights, enhancing risk detection and mitigation.

Q10. What are the benefits of effective Supply Chain Risk Management? ▶

- Reduced shipment delays and disruptions

- Minimized cargo damage and loss

- Lower financial and operational risks

- Increased supplier and carrier reliability

- Enhanced customer satisfaction and trust